Weight

body: 48 kg (w cover + 5 kg)

legs & pedal: 5 kg (w cover + 2 kg)

body: 48 kg (w cover + 5 kg)

legs & pedal: 5 kg (w cover + 2 kg)

25 x 75 x 137 / 90 cm (cover + 2 cm)

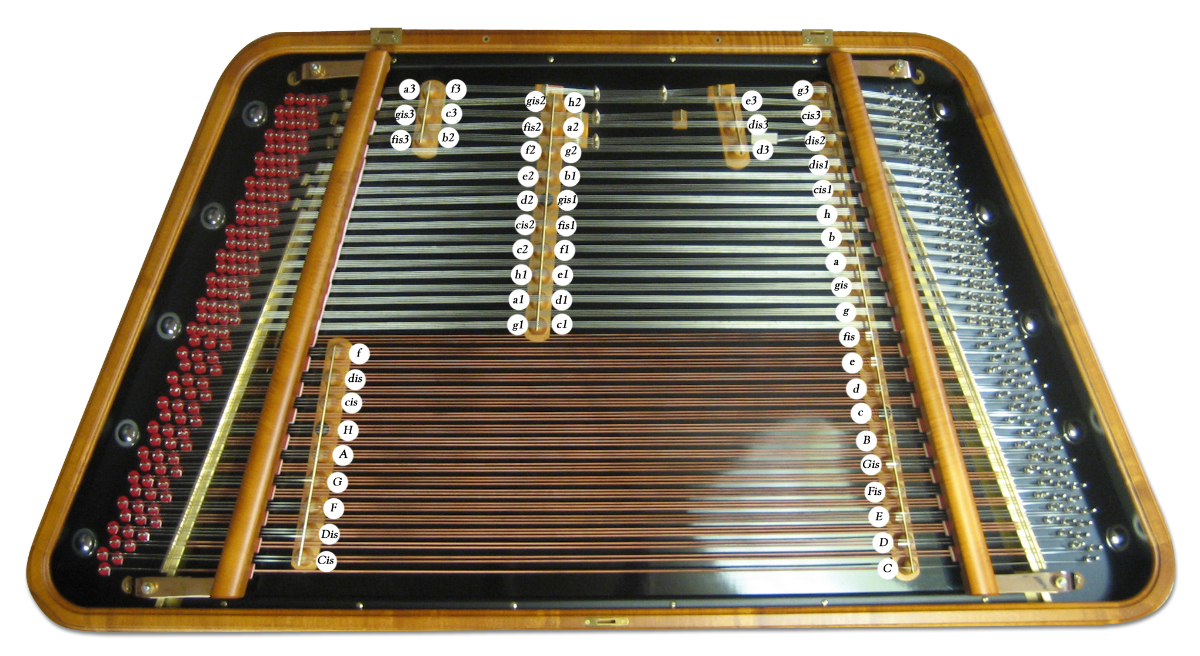

C-a3

Our Light, Classic and Standard cimbaloms have a traditional range (C-a3) and tuning. The tuning system is depicted in the picture.

The structure of a freshly constructed instrument needs some time to settle down. During this process, a lowering of the pitch of the tuning occurs. Therefore, the cimbalom has to be tuned frequently during the first few months after its purchase. To achieve the best results with a new cimbalom, a special attention has to be paid to its tuning, and the correct pitch of the tuning has to be observed (a1= 440 Hz).

The highest quality of tuning is undoubtedly secured by a certified tuner. In the area of Brno and its surrounding, we recommend tuners, with whom we frequently cooperate:

Jiří Pavelka, tel.: 737 488 405

Daniel Kikta

Tel.: 603 427 171

www.kikta.wz.cz

We grant a 5 year guarantee for our instruments (beginning with the date of purchase). Our company commits itself to fix (free of charge) any defects that are found on the instrument after the expiry of the guarantee period, that are caused by faulty design, second-rate material, or by an error that occured during the manufacturing of the product. Terms and conditions of the guarantee are that the instrument be placed in a room with a relative air humidity of 40-60%, and a temperature of 18–25°C (64,5 – 77°F).

The cimbalom should never be exposed to such effects of the environment, which do not correspond with the conditions described above (never place the cimbalom near a radiator, under direct solar radiation, or in a damp place etc.).

The tightness of the „head“ screws at the bottom of the cimbalom has to be checked regularly.

The guarantee does not apply to any damages caused by the owner, or by a third person, brought about by violation of the above mentioned conditions, or by an unqualified manipulation with the instrument. Nor does it apply to ordinary wear and tear, and the effects of regular tuning.

The purchaser is requested to claim an incidental damage without an unnecessary delay, as soon as they find the damage.

The travel and transport expenses, connected with the guarantee repair, are at the expense of the purchaser.